Science

The Monk Who Saw the Future: Did an 11th-Century Benedictine Beat Astronomers?

17 February 2026

Scientists from Columbia University managed to fit the power of an industrial laser onto a surface smaller than a fingernail. This revolutionary high-power laser chip, which was born by accident, may completely transform data transmission.

A few years ago, Michal Lipson’s team worked on improving LiDAR—a technology that uses light waves to measure distance. They were designing high-power chips that would emit brighter light beams. However, they noticed something unusual during their experiments.

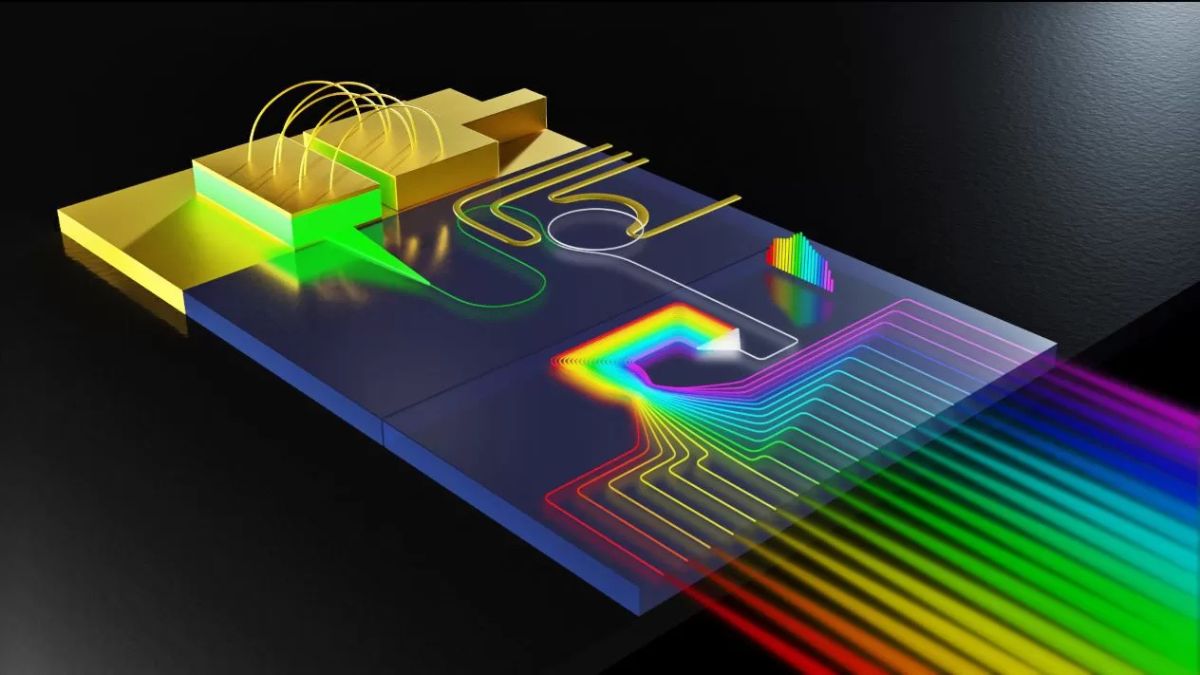

“When we sent more and more energy through the chip, we noticed that something we called a frequency comb formed,” says Andres Gil-Molina, one of the researchers, quoted in a Columbia University press release. A frequency comb is a special type of light that contains dozens of colors arranged next to each other in an ordered pattern—a bit like a rainbow. Each color shines brightly, while the gaps between them remain dark.

On a spectrogram, these bright frequencies look like the teeth of a comb. During research into this unusual light formation, it turned out that each “tooth” could function as a separate data transmission channel. This discovery, published in the journal Nature Photonics, could lead to a technological revolution.

Previously, creating a powerful frequency comb required large, expensive lasers and amplifiers. Lipson’s team showed how to achieve the same result on a single chip.

The scientists asked themselves: what is the most powerful laser we can place on a chip? They ultimately chose a multi-mode laser diode—a type used in medical devices and laser cutting tools. These devices produce enormous amounts of light, but the beam is chaotic, making it difficult to use for processes requiring precision.

“We used a locking mechanism to clean up this powerful but very noisy light source,” explains Gil-Molina. The method involves using silicon photonics to transform and clean up the laser’s output point. This creates a much cleaner, more stable beam.

After cleaning the light, the chip divides the single beam into dozens of evenly spaced colors. This creates the “frequency comb,” which combines the raw power of an industrial laser with the precision required for advanced communication. This is the high-power laser chip fit onto a record-small surface.

“Data centers have created a huge demand for powerful and efficient light sources that contain many wavelengths,” emphasizes Gil-Molina. “The technology we developed converts a very powerful laser into dozens of clean, high-power channels on a chip. You can replace racks of individual lasers with one compact device, lowering costs, saving space, and opening the door to much faster, more energy-efficient systems.”

Beyond data centers, the chips developed by the researchers could also enable the creation of portable spectrometers. They can also be applied in ultra-precise optical clocks, compact quantum devices, and even the advanced LiDAR systems, where the story of this extraordinary accidental discovery began.

Read this article in Polish: Chip z laserem o mocy fabryki. Naukowcy stworzyli go przez przypadek

Science

17 February 2026

Zmień tryb na ciemny