Science

Lost on the Moon for 60 Years: AI Joins the Search

23 February 2026

Small, inconspicuous, yet crucial – the planetary roller screw is a component that could decide the future of humanoid robots. Experts warn: whoever gains control over its production may dictate the terms in the global technological race. And China is already several steps ahead of the competition.

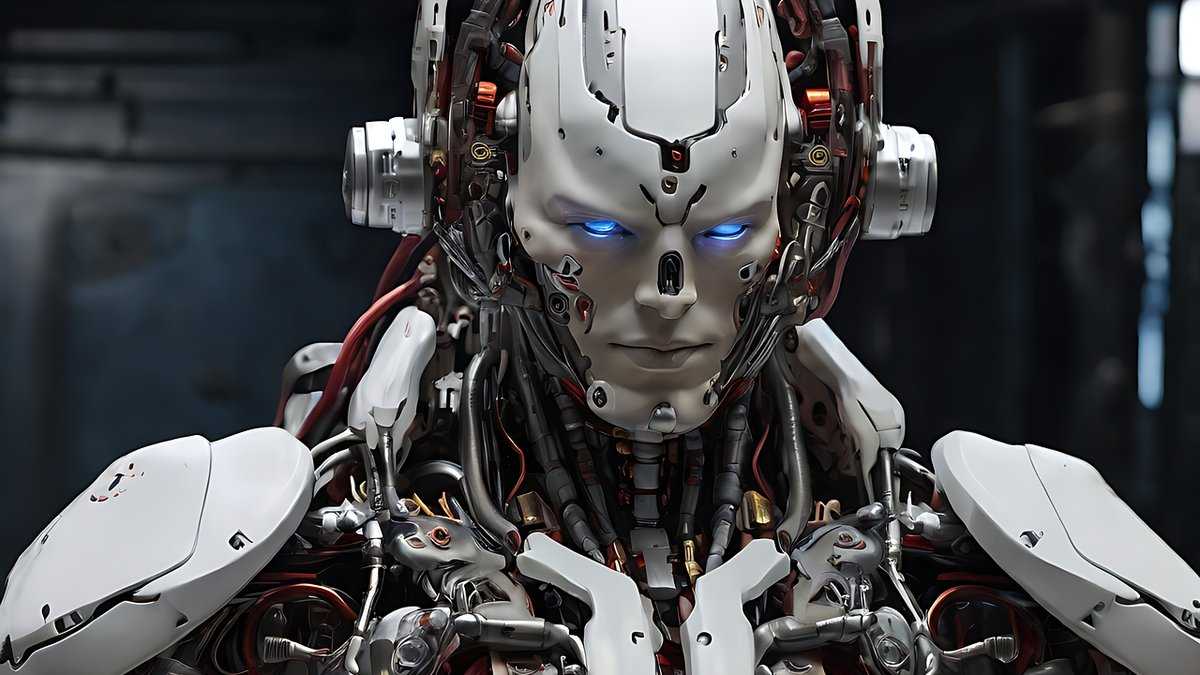

The widespread application of humanoid robots is no longer just a vision from science fiction films. Increasingly, they’re appearing in production halls and warehouses, collaborating with humans as equals. Powered by artificial intelligence, these machines can recognize their surroundings, react to commands, and move more naturally. However, even the most advanced software isn’t enough if a robot lacks an appropriately designed “body.” This is precisely where the planetary roller screw becomes indispensable for their sophisticated movement.

What’s needed is not just software, but also a solid construction – a skeleton full of motors, gears, bearings… and screws. The use of planetary roller screws is particularly crucial for the production of humanoid robots.

“Over time, planetary roller screws should constitute the majority of screws used in humanoids,” analysts at investment bank Morgan Stanley wrote in February 2025.

Read more: My Robotic Boyfriend: Will Humans Fall for Robots?

The application of humanoid robots requires solutions that can withstand intensive work and heavy loads. This is where planetary roller screws come in – a more advanced version of classic ball screws. Thanks to their design, they are more durable, precise, and long-lasting, making them an ideal choice for machines that move in a human-like manner. That’s why they are increasingly replacing older technologies, setting a new standard in robotics.

An example is Optimus, Tesla’s humanoid, which uses four planetary roller screws installed in its calves. Similar solutions are also employed by companies like Figure AI, Agility, 1X, as well as most Chinese manufacturers of humanoid robots.

“Actuators are the crown jewel of a robot’s core moving parts. They convert rotary motion into linear motion, which is a key function in robotics, especially for humanoid robots. They’re very accurate because we get good precision conversion from an angle to linear distance traveled. Traditionally, linear drives don’t do well under high loads, but rotary drives do,” explains Jonathan Aitken, a robotics expert at the University of Sheffield, in an interview with Fast Company.

It is precisely thanks to them that a robot can move smoothly and perform both precise gestures and heavier physical work. In short: without such components, there’s no question of humanoid machines capable of independent functioning in a human environment and widespread application of humanoid robots.

Modern technology comes at a price, and in the case of planetary roller screws, it is particularly high. According to J.P. Morgan data, one such screw costs between $1,350 and $2,700. And an average humanoid robot needs 40 or more of them. This means that the screws alone can account for up to one-third of the machine’s construction costs.

“Most of the costs associated with humanoids will be in the actuators,” confirms Scott Walter, technical advisor at Visual Components and one of the world’s leading experts in robot design.

The application of humanoid robots requires precise and durable components, and one alternative is rotary actuators, which can replicate human movements. While their use in all joints seems logical – as Scott Walter notes, their axis can also function as a joint – cost remains a barrier. The production of such components is currently more expensive, which limits their broader implementation.

See also: AI’s Double-Edged Sword: Innovation versus Security

Where the West sees difficulties, China sees opportunity. For years, the Middle Kingdom has been investing in the development of the precision components industry. Thanks to the earlier development of the drone industry, the country already has a base of actuator manufacturers who are now ready to engage in large-scale production of planetary roller screws.

In October 2024, Shanghai Beite Technology announced the construction of a new factory. Previously, it specialized in automotive parts. The new investment, worth $260 million, will be dedicated to the production of planetary roller screws.

Western companies must now catch up. The problem isn’t just a lack of ready factories; it’s also a shortage of specialized suppliers. They could ensure the high quality of these components on a mass scale. An additional challenge is the trade tensions between the USA and China, which could further hinder access to key components. For now, there isn’t even a cohesive strategy regarding what an independent Western supply chain would look like.

Although to a layperson it’s just a metal detail, in the world of robotics, the planetary roller screw has become a symbol of the impending revolution. It determines whether robots will be able to move safely, efficiently, and effectively.

The applications of humanoid robots are constantly expanding, and with it, the demand for key components like planetary roller screws is growing. Experts agree – demand for them will increase at a rapid pace. According to Jack Li, Head of R&D at Nanjing Process Equipment, the value of the robot screw market is very high. It already reaches $1.8 billion today. Over the next five years, the market value is expected to grow by over 30 percent annually. This is an excellent example of the broad application of humanoid robots.

The humanoid revolution is just beginning, but it’s already clear that without these inconspicuous, precise screws, it won’t move an inch.

Science

22 February 2026

Zmień tryb na ciemny