Science

The Monk Who Saw the Future: Did an 11th-Century Benedictine Beat Astronomers?

17 February 2026

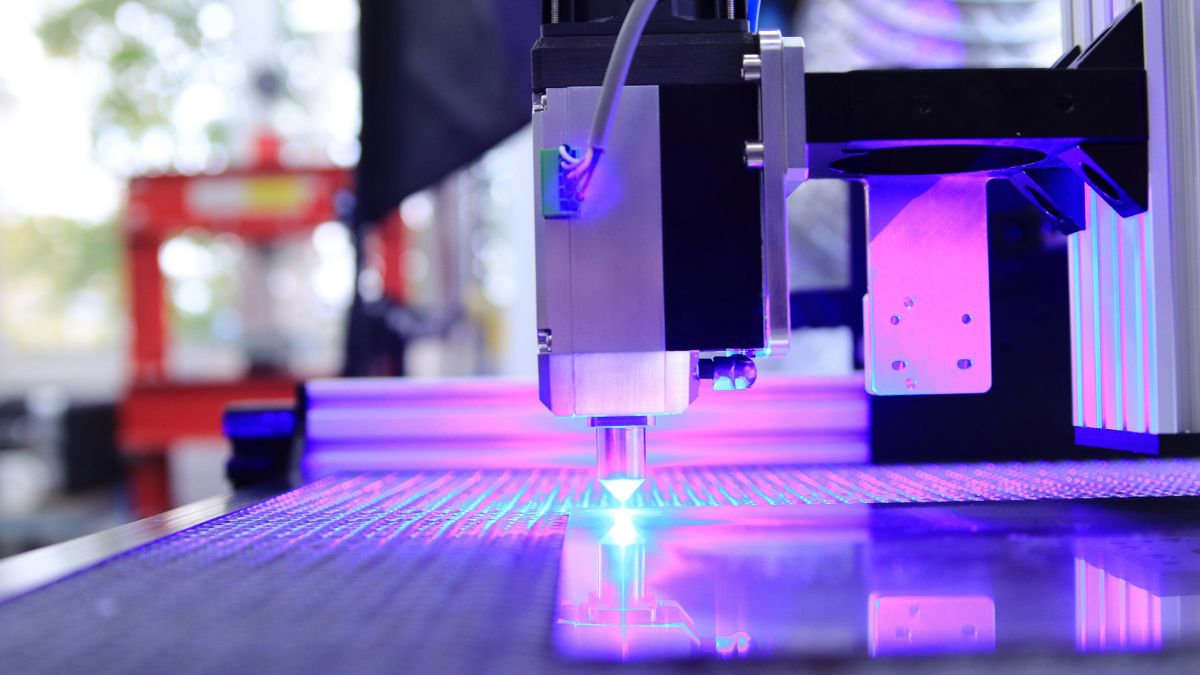

Swiss researchers at the École Polytechnique Fédérale de Lausanne (EPFL) have devised a technique that could change the manufacturing industry. Instead of deciding on the metal type before printing, they choose it after the process is complete. The metal is then "grown" layer by layer within a special hydrogel. The result? Metal structures up to 20 times stronger than previously possible, kicking off a true metal 3D printing revolution.

Traditional 3D printing techniques using metals and ceramics struggle with a critical problem. After the entire process concludes, materials can shrink by as much as 90%. Furthermore, they become porous and brittle.

To increase their strength, manufacturers have previously used a process called vat photopolymerization. This involved adding metal fragments to a light-sensitive plastic (polymer) to harden it. However, this solution had its clear drawbacks.

The fundamental issue was that the metal shrank as it solidified, ultimately making the structure more porous and less durable. The metal particles were added while the base material was still liquid. Evidently, this sequence was the problem, as the significant shrinkage occurred during solidification. Swiss materials scientists decided to completely invert the entire process. They described their method in the journal Advanced Materials.

The EPFL team first prints the desired shape using a water-based hydrogel material. This “template” is then soaked in the appropriate metal salts. This is where the magic happens: the material choice is made here—researchers can choose copper, iron, silver, or even ceramics (using different substances instead of metal salts).

During the soaking process, the hydrogel absorbs the salt solution like a sponge. Then, a special chemical reaction converts the salt into metal. The entire process is then repeated five to ten times. Layer by layer, the tiny metal particles solidify within the hydrogel, which finally burns away in the furnace. What remains is a metallic (or ceramic) structure with the exact shape of the original 3D-printed template.

“Our work does not only enable the fabrication of high-quality metals and ceramics using an accessible, low-cost 3D printing process. It also underscores a new paradigm in additive manufacturing, where material selection occurs after the 3D printing, not before it,” emphasizes Daryl Yee, head of the Materials Chemistry and Manufacturing Laboratory at EPFL.

The scientists tested their method by printing complex geometric solids called gyroids using iron, silver, and copper. The results were spectacular.

“Our materials could withstand 20 times higher pressure compared to those produced by previous methods, showing only 20 percent shrinkage compared to 60–90 percent,” says PhD student Yiming Ji, the lead author of the study.

These properties mean that 3D printing can now create metal objects previously impossible to manufacture. Sensors, biomedical devices, and energy conversion systems—anywhere strength, lightness, and complex geometry are simultaneously required—the new method may find its application. This truly marks a metal 3D printing revolution.

The method has one current flaw: time. The necessity of repeated saturation makes the overall process longer than other techniques. “We are already working on reducing the total manufacturing time by utilizing a robot for automation,” announces Yee. If perfected, this method could signal the true metal 3D printing revolution in metal and ceramic manufacturing.

Read this article in Polish: Rewolucja w druku 3D: metal można wyhodować

Science

17 February 2026

Zmień tryb na ciemny